Ungayisebenzisa kanjani i-exciter yesikrini esidlidlizayo ngendlela efanele?

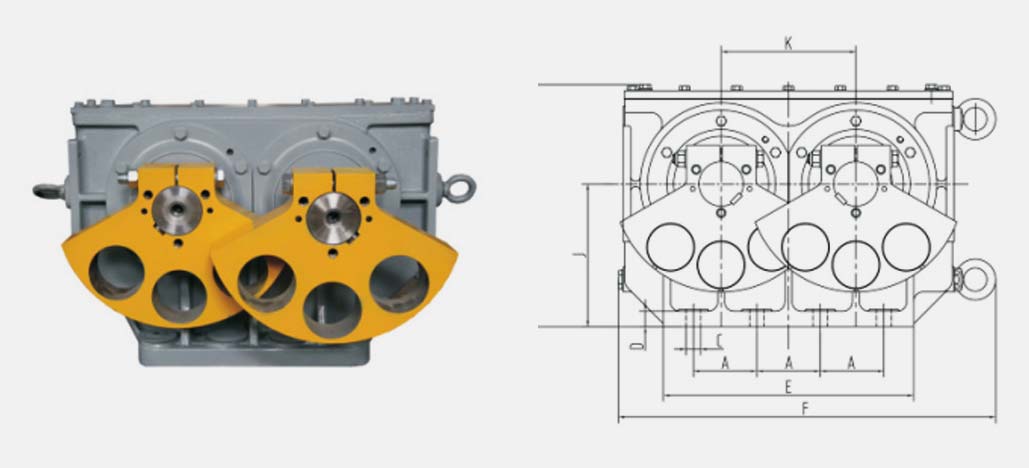

Sonke siyazi ukuthi uma imishini nemishini ethile idinga ukukhiqiza amandla avusa amadlingozi, uma umshini ngokwawo ungenawo lo msebenzi, udinga ukwengeza izisetshenziswa zokudlidliza. Isikrini esidlidlizayo sidinga ukusebenzisa ukudlidliza komshini ukuze sibuke izinto. Ngakho-ke, ukudlidliza I-exciter yesikrini isibe enye yezingxenye ezibalulekile zesikrini esidlidlizayo.

Uma uthenga i-exciter yesikrini esidlidlizayo, abasebenzisi abaningi ngokuvamile bagxila kukhwalithi nokusebenza kwe-exciter. Nokho, inqobo nje uma ikhwalithi idluliswa, ingabe ukusetshenziswa kwe-exciter yesikrini esidlidlizayo kungaqinisekiswa ngokuphelele? Akunjalo. Nakuba ikhwalithi ye-exciter igxile ekunakeni, ukusetshenziswa kwe-exciter kulungile futhi kunengqondo, futhi kuyisici esibalulekile esithinta ukusebenza kwesikrini esidlidlizayo. Uma isetshenziswa ngendlela engafanele isikhathi eside, kulula ukubangela ukwehluleka kwe-exciter, ngaleyo ndlela kuthinte ukusebenza okuvamile kwesikrini sokudlidliza. Njengomkhiqizi wakudala wesikrini esidlidlizayo, i-Luoyang Haiside Heavy Industry Co., Ltd. yabelana nawe ngezinyathelo zokuphepha zokusetshenziswa kwezivuseleli zesikrini ezidlidlizayo, ukuze abantu abaningi bafunde ukusetshenziswa okulungile kwe-exciter yesikrini esidlidlizayo.

Ukusetshenziswa okulungile kwe-exciter yesikrini esidlidlizayo kufinyezwa kanje:

1. Ngaphambi kokuqala umsebenzi, hlola ukuqina kwawo wonke ama-bolts, futhi ngemva komsebenzi wokuqala amahora angu-8, hlola ukuthi kukhona ukuxega futhi uqinise futhi.

2. Hlola izinga lamafutha ku-exciter. Uma izinga lamafutha liphezulu kakhulu, izinga lokushisa le-exciter lizokhuphuka noma kuyoba nzima ukusebenza. Uma izinga lamafutha liphansi kakhulu, lizoholela ekugcobeni okunganele kanye nokulimala ekuthwaleni. Ngokuvamile, i-2/3 yendawo yokugcoba kufanele igcwaliswe. kufanele.

3. Qinisekisa ukuthi kuvunyelwana kancane phakathi kwazo zonke izingxenye ezihambayo nezinto ezingashintshi.

4. Uma umthwalo wesikrini sokudlidliza uqala, kuzodala ingcindezi enkulu ekuthwaleni i-exciter futhi kunciphise impilo yesevisi. Ngakho-ke, kuyadingeka ukuhlola indawo yesikrini yesikrini esidlidlizayo ngaphambi kokuvula ukuze uqinisekise ukuthi isikrini esidlidlizayo siqalwa ngaphansi komthwalo, bese uqala ukudla ngemva kokuba isikrini esidlidlizayo sisebenza kahle. Ngaphambi kokuvala, ukuphakela kufanele kumiswe kuqala, futhi umshini kufanele uvalwe ngemva kokukhipha izinto ezisesibukweni.

5. Ngesikhathi sokusebenza kwesikrini esidlidlizayo, naka ukuthi i-exciter iyashisa yini noma inomsindo ongajwayelekile. Uma kukhona ukuhlinzwa okungajwayelekile, kumise kusenesikhathi ukuze uhlole ukuze ugweme izingozi.

6. Uma uqaqa i-exciter, idinga ukucishwa kusengaphambili, futhi kufanele ibhekisele kumdwebo womhlangano we-exciter. Kufanele ihlakazwe ngamathuluzi akhethekile ukuze ugweme ukulimala okwenziwa ezingxenyeni. Ngemuva kokuhlanza nokuhlola izingxenye, uma ukuqhekeka, ukugqoka nezinye izinkinga kutholakala, kufanele kushintshwe ngesikhathi.

I-Haiside Heavy Industry ikholelwa ukuthi inqobo nje uma i-exciter yomkhiqizo endala ehlangabezana nezindinganiso zamazwe ahlukahlukene ikhethiwe, futhi i-vibration exciter isetshenziswa ngokuvumelana nezindinganiso phakathi nokusetshenziswa kwe-exciter yesikrini esidlidlizayo, ukusebenza kwe-exciter kungaba ngokuyisisekelo okuqinisekisiwe. Ama-exciter esikrini esidlidlizayo akhiqizwe i-Haiside Heavy Industry anebanga eliphelele nekhwalithi enhle kakhulu, futhi asetshenziswa kakhulu ezikrinini ezidlidlizayo ezihlukahlukene. Uma unezidingo ezihlobene, ungasishayela noma kunini.