Izinzuzo Zokusebenzisa Isibonisi Esidlidliza Esivame Kakhulu Ekuhlolweni Kwezimboni

Ezimbonini ezifana nezezimayini, ukumba amatshe, izinto zokwakha, kanye nokucubungula amakhemikhali, ukuhlolwa kwezinto ezisebenzayo kuyisinyathelo esibalulekile esithinta ngqo ikhwalithi yomkhiqizo, amandla okukhiqiza, kanye nezindleko zokusebenza. Njengoba imininingwane yezinto iba nzima kakhulu—ikakhulukazi ezinhlayiyeni ezincane nezincane kakhulu—izindlela zokuhlola ezivamile eziphansi zivame ukuba nzima ukuletha imiphumela ezinzile nenembile.

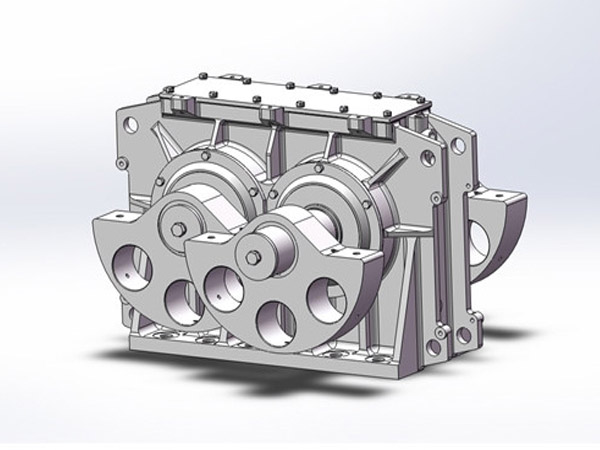

Yilapho i-exciter yesikrini esidlidlizayo esivame kakhulu iba yingxenye ebalulekile yokuthuthukisa ukusebenza. Ngokunikeza ukudlidliza okulawulwayo, okushesha kakhulu, kuthuthukisa kakhulu ukunemba kokuhlola, kunciphisa isikhathi sokungasebenzi, futhi kwandisa ukusebenza kahle kwesitshalo sonke. Ngezansi, sihlola izinzuzo ezinkulu zokusebenzisa i-exciter yesikrini esidlidlizayo esivame kakhulu ezisetshenziswa zezimboni zanamuhla.

Izinzuzo Zokusebenzisa Isibonisi Sesikrini Esidlidliza Esivame Kakhulu

1. Ukusebenza Kahle Kokuhlola Okuthuthukisiwe Kakhulu

Enye yezinzuzo eziphawuleka kakhulu ze-exciter yesikrini esidlidliza ngesivinini esikhulu yikhono layo lokuthuthukisa kakhulu ukusebenza kahle kokuhlola. Imvamisa yokudlidliza okusheshayo idala ukunyakaza okukhulu kwezinhlayiya ebusweni besikrini, okuvumela izinto ezincane ukuthi zidlule kalula ku-mesh.

Uma kuqhathaniswa nezi-exciter ezivamile, amayunithi emvamisa ephezulu asebenza kahle kakhulu lapho kuphathwa:

Isihlabathi esihle kanye nezinhlanganisela zamaminerali

Ama-slurries nezinto ezimanzi

Izimpuphu ezi-ultra-fine ezisetshenziswa ekucutshungulweni kwamakhemikhali noma kwezimboni

Ngokusheshisa ukuhlukaniswa kwezinhlayiya, izitshalo zingafinyelela umphumela ophezulu ngaphandle kokulahlekelwa ukunemba, okuholela ekulinganisweni komkhiqizo okuhlala njalo kanye nokusebenza okuthuthukisiwe kwe-downstream.

2. Ukuhlelwa Kwezinto Ezingcono Nokunciphisa Ukufiphala

Ukudlidliza kwemvamisa ephezulu kukhuthaza ukuhlukaniswa kwezinto okusebenzayo. Izinhlayiya ezincane zidonswa phansi ziye ezimbotsheni zesikrini, kuyilapho izinhlayiya ezinkulu zihlala phezu kobuso futhi ziya ekukhishweni. Le nqubo yokuhlukanisa eqhubekayo inciphisa ukuhlukaniswa kwezinto futhi inciphisa izinkinga ezivamile njengokufiphaza isikrini kanye nokuvaleka.

Emisebenzini yokucubungula ama-ore, ama-aggregates, noma izinto ezinomswakama ophezulu, ukuhlukaniswa okuthuthukisiwe kusho:

Ukuphazamiseka okumbalwa ngesikhathi sokusebenza

Ukusebenza kokuhlola okuzinzile kakhulu

Isidingo esinciphile sokuhlanza ngesandla noma ukungenelela

Lokhu kunegalelo ekusebenzeni kwesitshalo okubushelelezi kanye nokuthembeka okuphezulu.

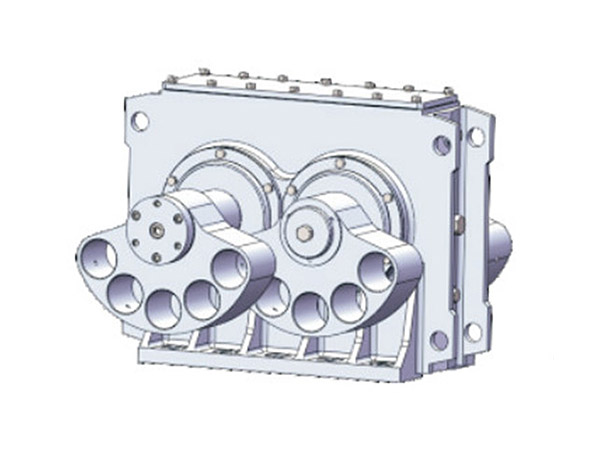

3. Isakhiwo Esincane Esinomthamo Ophezulu Wokukhipha

Enye inzuzo yezici zokucindezela isikrini ezidlidliza kakhulu yikhono lazo lokuletha ukusebenza okuqinile kokuhlola ngomklamo omncane. Ngenxa yokuthi isici sokukhulisa ukusebenza kahle kokuhlola, indawo yesikrini edingekayo ingancishiswa ngaphandle kokuphazamisa umphumela.

Lokhu kuzuzisa kakhulu:

Amaphrojekthi okuvuselela izitshalo ezikhona

Imigqa yokukhiqiza enesikhala esincane sokufaka

Izinhlelo zokuhlola zeselula noma ze-modular

Indawo encane ehlanganiswe nokukhiqiza okuphezulu ivumela abaklami bezitshalo ukuguquguquka okukhulu ngenkathi begcina noma bekhulisa amandla okucubungula.

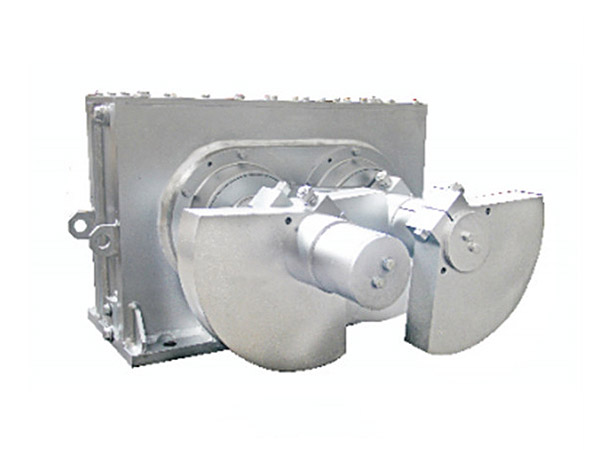

4. Izidingo Zokunakekelwa Nokugqokwa Okuphansi

Izici zokudlidliza ezilungiselelwe kahle zisiza ekunciphiseni umthelela ongadingekile kanye nokungqubuzana phakathi kwezinto zokwakha kanye nobuso besikrini. Ngenxa yalokho, izingxenye ezibalulekile ezifana nama-screen meshes, ama-bearings, kanye nezingxenye zesakhiwo zibhekana nokucindezeleka okuncane komshini.

Ngamazwi angokoqobo, lokhu kusho ukuthi:

Impilo yesevisi ende yamaphaneli esikrini

Ukuvalwa okuncishisiwe kokuvama kokulungisa

Ukusetshenziswa kwezingxenye ezisele okuphansi ngokuhamba kwesikhathi

Kubasebenzi bezitshalo, lezi zinzuzo zihumusha ngqo ezindleleni zokulungisa eziphansi kanye nokutholakala kwemishini okuthuthukisiwe.

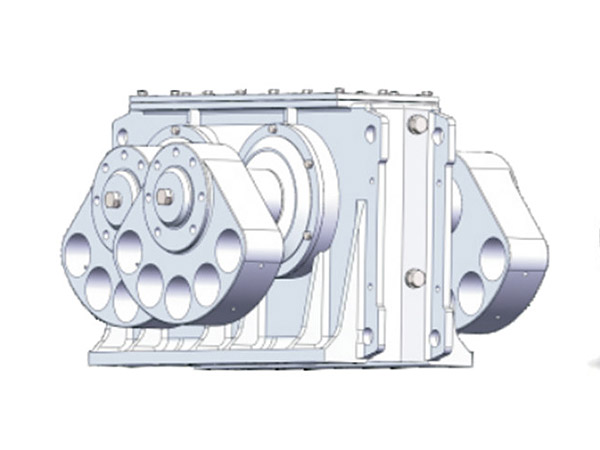

5. Ukuzivumelanisa Nezimo Okuphezulu Kwezinto Nezinqubo Ezihlukahlukene

Ama-exciter esikrinini adlidliza kakhulu alungiseka kakhulu futhi angalungiswa kahle ngokwezakhiwo zezinto ezifana nosayizi wezinhlayiya, ubuningi, kanye nokuqukethwe komswakama. Lokhu kuzenza zifaneleke ezinhlobonhlobo zezicelo, okuhlanganisa:

Ama-aggregate aqinile nacolekile

Ama-ore ensimbi nangeyona insimbi

Amaminerali kanye nama-powder ezimboni

Ngokulungiswa okufanele, uhlelo olulodwa lokuhlola lungaphatha izinhlobo eziningi zezinto, lunciphise isidingo semishini eyengeziwe futhi luthuthukise ukuguquguquka kokukhiqiza.

6. Ukusebenza Okusebenzisa Amandla Kahle

Nakuba ama-exciter asebenza ngesivinini esiphezulu asebenza ngesivinini esiphezulu, avame ukonga amandla kakhulu kunezinhlelo zendabuko. Ngokuthuthukisa ukunyakaza kwezinto kanye nokunciphisa isikhathi sokuhlola, kuchithwa amandla amancane ekuhlukaniseni okuphindaphindiwe noma okungasebenzi kahle.

Ngokusebenza isikhathi eside, lokhu kuholela ku:

Ukusetshenziswa kwamandla okuphansi ngethani ngalinye okucutshungulwayo

Izindleko zokusebenza ezincishisiwe

Ukusebenza okuthuthukisiwe kokuzinza

Ezinkampanini ezigxile ekulawuleni izindleko kanye nomthwalo wemfanelo wemvelo, ukusebenza kahle kwamandla kuyinto ebaluleke kakhulu.

Isiphetho

Isivuvuzi sesikrini esidlidliza ngesivinini esiphezulu singaphezu nje kwengxenye—siwukuthuthukiswa kokusebenza kwayo yonke isistimu yokuhlola. Ngokuthuthukisa ukusebenza kahle kokuhlukaniswa, ukunciphisa izidingo zokugcinwa, nokusekela ukucubungula izinto eziguquguqukayo, kusiza imisebenzi yezimboni ukufeza umkhiqizo ophezulu ngengozi yokusebenza ephansi.

Ezindaweni zokumba, zokwakha, kanye nezimboni zokucubungula ezifuna umkhiqizo ozinzile kanye nokonga izindleko zesikhathi eside, ukutshala imali kubuchwepheshe besivuvuzi sesikrini esidlidliza ngesivinini esiphezulu kuyisisombululo esisebenzayo nesilungele ikusasa.