Yini okufanele ngiyenze uma isikrini esidlidlizayo siphuma?

Ekukhiqizweni kwansuku zonke, ngesikhathi sokusetshenziswa kwesikrini esidlidlizayo, ukudlulisa okubonakalayo okusobala akusheleli kungazelelwe, kulandelwa inkinga yokuthi ukukhishwa kuchemile ohlangothini oluthile. Ukuze sixazulule le nkinga, kufanele siqale sithole isizathu sokuphambuka kwento, bese sithola ukuthi singayixazulula kanjani inkinga yokuphambuka kwesikrini esidlidlizayo. Ephendula izinkinga ezingenhla, umenzi wesikrini esidlikizayo usinike isingeniso esinemininingwane.

Isizathu sokuchezuka kwesikrini esidlidlizayo

1. Isikrini esidlidlizayo sinesikhathi eside sokusebenza

Isikrini esidlidlizayo sinomthwalo omkhulu wokusebenza kanye nempilo ende yokusebenza. Esikrinini esikhulu sokudlidliza esiwumugqa, ngenxa yesisindo saso esinzima, uma sihambisana nokudlidliza okuphindaphindiwe kanye ne-inertia enamandla iminyaka eminingi, ezinye izingxenye zomzimba zizoxega, okuzoholela ekudlidlizeni. I-engeli ye-motor iyashintsha, ngakho-ke kwenzeka ukuchezuka kokukhipha.

2. Ukondla ngokungalingani

Uma isikrini esidlidlizayo sidla kakhulu noma ngaphansi, kulula ukubangela ukunemba kokuhlola okungazinzile, futhi ngenxa yezinto ezithe xaxa noma ezingaphansi, ukuchezuka kwamandla kukhulu, futhi kunenkinga yokuthi ukukhishwa kuchemile ohlangothini olulodwa. .

3. Inkinga yokufaka i-Exciter

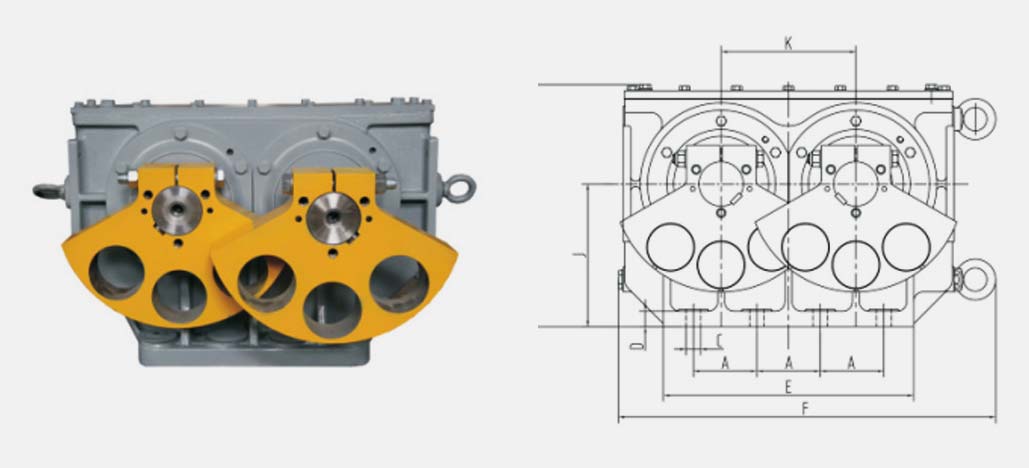

Ukuthuthwa nokuhlolwa kwezinto ngesikrini esidlidlizayo kuphushwa i-exciter yokudlidliza ukuya kokokusebenza ngamandla amakhulu ashukumisayo endaweni eklanyelwe engashintshi. Ngakho-ke, uma impahla edluliswayo ingezinhle, ngokwesisekelo ingabhekwa njenge-exciter yokudlidliza. Kunenkinga nge-engeli yokufaka. Ngaphansi kwezimo ezijwayelekile, umkhiqizi uzokwenza ukufaka okunembayo, ukuhlola, kanye nokulungisa ngaphambi kokuba okokusebenza kuhambe efekthri ukuze kugwenywe ukuchezuka kwesikhombisi-ndlela samandla ashukumisayo, ngakho le nkinga ngokuvamile ayiyona imbangela yomshini omusha.

4. Iphutha lesisindo somzimba wesikrini ngokwawo likhulu

Iphutha lesisindo somzimba wesikrini esidlidlizayo ngokwawo likhulu, futhi indawo emaphakathi namandla adonsela phansi ayinembile. Ngokuvamile, lolu hlobo lwenkinga alukho kubakhiqizi abavamile, kodwa manje imakethe iyisiphithiphithi, abanye abakhiqizi bathengisa izikrini zokulingisa ezisezingeni eliphansi ngamanani emakethe angavamile, nakuba ukubukeka kufana, kodwa empeleni akukho okuqukethwe kwezobuchwepheshe.

5. Ukuqina kwentwasahlobo okumanzisa okungaguquki

Ukuqina kwesiphethu esimanzi akuhambisani, futhi uma sonakalisiwe, kuzophinde kubangele ukuthi isikrini esidlidlizayo siphume. Ukubaluleka kwesiphethu esimanzi esikrinini esidlidlizayo akukhona ngaphansi kwalokho kwenjini edlidlizayo. Uma ikhwalithi yentwasahlobo ebamba ukushaqeka ingahlangabezani nezidingo zemakethe, nakanjani izobangela uchungechunge lwezinkinga zokukhiqiza.

6. Izinguquko endaweni yokusekelwa kwentwasahlobo

Ukushintsha kwendiza eyisisekelo yokufaka kanye nendawo yosekelo lwentwasahlobo kuzobangela ukukhishwa kwesikrini esidlidlizayo kube nokuchema. Ngaphezu kwe-exciter yokudlidliza enikeza amandla omthombo wokuhlola oyinhloko esikrinini esidlidlizayo, isipringi esincibilikayo sokudlidliza, ibhola eligxumayo, iringi yerabha evalekayo, njll., ekhona ngenxa yokumuncwa ukushaqeka, nakho kuthinta amandla esikrini esidlidlizayo kanye nesikrini esidlidlizayo okwengeziwe. noma ngaphansi. Izinga lomzimba lizinzile. Uma ingxenye ethile inezinkinga ezifana nokuguga, izobangelwa indawo yesikrini engalingani kanye nokungazinzi komshini wesikrini, okuzobangela inkinga yokuphambuka kwesiqondiso sokukhipha. Inkinga inciphe kakhulu, ngakho ukuhlolwa nokugcinwa njalo kubaluleke kakhulu.

7. Ukuguqulwa kwebhokisi lesikrini

Ibhokisi lesikrini libhekisela esikrinini esingaphezulu kwe-exciter nangaphansi kwembobo yokuphakela, esakhiwe ifremu yesikrini kanye nendawo yesikrini egxilile kuyo. Uma isikrini esidlidlizayo sisebenza ngokujwayelekile, ikakhulukazi okokusebenza kwesilinganiso esikhulu nesinemvamisa ephezulu, ifreyimu yesikrini idinga kokubili amandla adonsela phansi ezinto zokuhlola ngobuningi kanye namandla okuvusa anamandla enjini edlidlizayo. Uma amandla enganele, kulula ukubangela ukuguqulwa nokulimala. , Isikrini esikhulu sokudlidliza sezimayini sidinga ukunaka ngokukhethekile le nkinga.

Isixazululo sokuchezuka kwesikrini esidlidlizayo

1. Uma isikhathi sokusebenza sesisetshenziswa sesikrini esidlidlizayo siside kakhulu, okokusebenza kufanele kunakekelwe njalo.

2. Ukudla kufanele kube okufanayo futhi kuqhubeke.

3. Faka kabusha i-exciter futhi ulungise indawo ye-exciter ngendlela efanele.

4. Abasebenzisi kufanele bathenge eduze futhi bakhethe ngokucophelela.

5. Amandla ebhokisi lesikrini akudingi nje kuphela izinto ezisetshenziswayo eziphezulu, kodwa futhi nenqubo ye-welding eyingqayizivele kanye nomklamo owengeziwe ozinzile.

Okungenhla kumayelana nezizathu zokuchezuka kwesikrini esidlidlizayo kanye nezixazululo ezihambisanayo. Eqinisweni, kungabonakala ngezizathu zokuthi ukuxazulula inkinga yokuphambuka kokukhishwa, into esemqoka ukugcinwa okuvamile kwemishini yesikrini esidlidlizayo, ukudla okufanayo, njll, futhi ngesikhathi esifanayo lapho ukhetha Uma ukhetha imishini, khetha okokusebenza kwesikrini sokudlidliza kwekhwalithi ephezulu okukhiqizwe abakhiqizi abajwayelekile.