How to design a vibrating screen

The design of a vibrating screen is a complex and meticulous process that requires comprehensive consideration of multiple aspects to ensure the performance, efficiency and reliability of the equipment.

Vibrating screen design

Overall design principles

Clear design goals: Determine design goals such as screening efficiency, processing capacity, wear resistance, etc. based on usage scenarios, material characteristics, and production capacity requirements.

Safety: Ensure the safety of the equipment during operation and maintenance, including setting emergency stop buttons, protective covers, and safety signs.

Easy to maintain: Provide sufficient maintenance channels and space for maintenance personnel to approach key components of the equipment for inspection and maintenance.

Structural design

Screen frame

Material selection: Constructed with materials with high strength and rigidity, such as steel plates, to support the weight of the entire screening system and the forces generated during operation.

Design points: Consider stress distribution, welding quality, and overall stability to ensure that the screen frame can withstand large vibration forces.

Screen mesh

Material selection: Select appropriate screen mesh materials according to material characteristics and screening requirements, such as high manganese steel with good wear resistance or corrosion-resistant 316 stainless steel.

Support structure: Ensure uniform tensioning of the screen mesh to obtain ideal screening effect. The design of the support structure should facilitate the installation, adjustment and replacement of the screen, while reducing the risk of material blockage and screen damage.

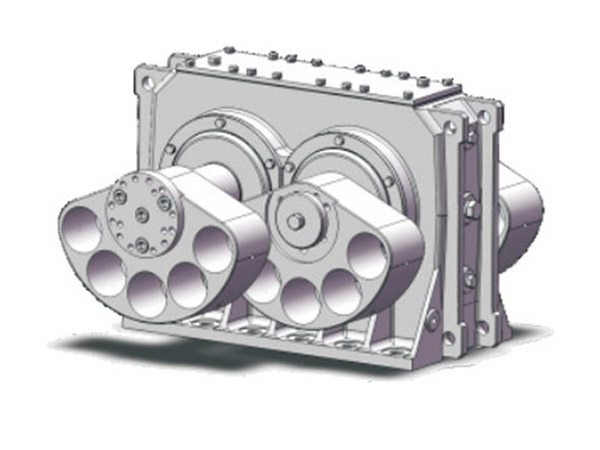

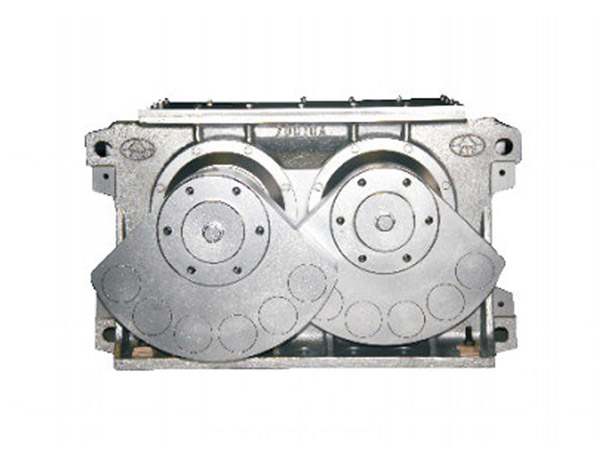

Vibrator

Type selection: Select a suitable vibrator according to the vibration mode and requirements of the vibrating screen, such as an eccentric block vibrator driven by a motor.

Performance matching: Ensure that the performance of the vibrator matches the requirements of the screening system, including the setting of parameters such as vibration frequency and amplitude.

Inlet and outlet

Position design: Determine the location of the inlet and outlet according to the process flow and site conditions to ensure that the material can smoothly enter and leave the screening system.

Sealing: The inlet and outlet should have good sealing to prevent material leakage and dust flying.

Support device

Function: The support device is an auxiliary component of the vibrating screen, which can ensure the smooth operation of the vibrating screen and reduce the noise of the vibrating screen.

Design points: Use elastic elements (such as springs or rubber pads) to isolate the vibration force and reduce the impact on the foundation and the surrounding environment.

Dynamic design

Vibration frequency

Selection basis: Determine the appropriate vibration frequency based on material characteristics, screen hole size and production capacity requirements. Too high a vibration frequency may lead to incomplete separation of materials, while too low a vibration frequency may reduce the screening efficiency.

Amplitude

Key points of control: Appropriate amplitude can improve screening efficiency, but too large an amplitude may cause the material to pass through the sieve holes prematurely, reducing the screening accuracy. Therefore, the amplitude needs to be precisely controlled to ensure the screening effect.

Vibration direction angle

Adjustment effect: By adjusting the vibration direction angle (i.e. the angle between the direction of the vibration force and the horizontal plane), the movement trajectory of the material on the screen surface can be changed to optimize the screening effect.

User interface and control system

User interface: Designed to be intuitive and easy to operate, including clear indicator lights, display screens and control buttons so that operators can monitor the status of the equipment and adjust operating parameters.

Control system: Use advanced control systems to achieve automated control, improve production efficiency and screening accuracy. The control system should have fault alarm and self-protection functions to ensure that the equipment can automatically shut down under abnormal conditions and protect key components from damage.

Other considerations

Wear resistance: Select materials and surface treatment technologies with good wear resistance (such as sandblasting, coating, thermal spraying, etc.) to extend the service life of the equipment and reduce maintenance costs.

Environmental protection: Consider the noise and dust pollution during the operation of the vibrating screen, and take corresponding measures to control and protect it.

Economic efficiency: Under the premise of ensuring the performance and quality of the equipment, reasonably control the design cost and manufacturing cost to improve the cost performance of the equipment.

In summary, the design of the vibrating screen is a complex process involving many aspects, which requires comprehensive consideration of factors such as mechanical structure, material selection, dynamic characteristics and operational convenience. Through meticulous design and strict quality control, a vibrating screen with superior performance, easy operation and low maintenance cost can be manufactured to meet the needs of different industrial applications.