Yiziphi izinhlobo zama-exciter esikrini esidlidlizayo?

Ama-exciter esikrini esidlidlizayo angamadivayisi ayimishini akhiqiza ukudlidliza okudingekayo ukuze kuhlolwe izinto ezimbonini ezifana nezimayini, i-metallurgy, nezokwakha. Kunezinhlobo ezimbalwa zama-exciter esikrini esidlidlizayo, ngasinye sinomklamo waso ohlukile kanye nendlela yokusebenza.

Izinhlobo Zokudlidliza Zesikrini

1. Ama-Electromagnetic Exciters:

Ukusebenza: Ama-exciter kagesi asebenzisa inkambu ye-electromagnetic ukuze enze ukunyakaza okudlidlizayo. Ukushintshana kwamanje okudlula kukhoyili kwakha indawo kazibuthe enyakazisa isikrini.

Ukusetshenziswa: Lokhu kuvame ukusetshenziselwa ukuhlolwa kwezinto ezinhle, lapho kudingeka khona ukudlidliza kwamafrikhwensi aphezulu.

2. Ama-Motor Angabhalansi (noma ama-Rotary) Exciters:

Ukusebenza: Lokhu kuhlanganisa injini enezisindo ezingalingani ezinamathiselwe kunoma yimuphi umkhawulo we-rotor shaft. Njengoba i-motor ijikeleza, izisindo ezingalingani zikhiqiza amandla amaphakathi, okwenza isikrini sidlidlize.

Ukusetshenziswa: Kuvamile kuzo zombili izikrini ezinyakazayo eziyindilinga nemigqa, lawa ma-exciters ahlukahlukene futhi asetshenziswa ezinhlelweni zokuhlola eziningi.

3. Ama-Gearbox Exciters:

Ukusebenza: Lawa ma-exciter asebenzisa u-gearbox oshayela ukunyakaza kokudlidliza kwesikrini. I-gearbox ngokuvamile iqukethe amagiya akhiqiza ukunyakaza okudlidliza okungaguquki lapho inikwa amandla yinjini kagesi.

Ukusetshenziswa: Ngokuvamile kusetshenziswa kuzinhlelo zokusebenza ezinzima lapho amandla okudlidliza adingeka khona, njengezikrini zezimayini.

4. Ama-Direct Drive Exciters:

Ukusebenza: Kuma-exciters okushayela okuqondile, ukudlidliza kukhiqizwa ngqo yinjini kagesi ngaphandle kwebhokisi le-gearbox eliphakathi nendawo noma ukuxhumana kwemishini. Injini ngokuvamile ifakwe ngqo esikrinini.

Ukusetshenziswa: Kusetshenziswa ekuhlolweni kwe-high-frequency kanye nokokusebenza okuhle, kunikeza ukulawula okunembile phezu kwefrikhwensi yokudlidliza.

5. Ama-Hydraulic Exciters:

Ukusebenza: Ama-hydraulic exciters asebenzisa uketshezi olunamanzi ukushayela ipiston noma i-actuator, edala ukunyakaza kokudlidliza. Isistimu ingalawulwa ngokunembile ukuze iguqule imvamisa kanye nobude bokudlidliza.

Ukusetshenziswa: Kuvamile ezinhlelweni ezidinga ukulawula okuguquguqukayo phezu kokudlidliza futhi kuvame ukusetshenziswa emsebenzini osindayo noma emisebenzini yokuhlola okukhethekile.

6. Ama-Eccentric Shaft Exciters:

Ukusebenza: Ama-exciter e-shaft e-eccentric ahlanganisa i-shaft ejikelezayo ene-offset mass (i-eccentric weight) eyenza ukunyakaza okuyisiyingi njengoba i-shaft ijikeleza.

Ukusetshenziswa: Kusetshenziswa kakhulu kuzikrini ezinyakazayo eziyindilinga, zithembekile futhi ziyasebenza ekuphatheni izinto ezinkulu.

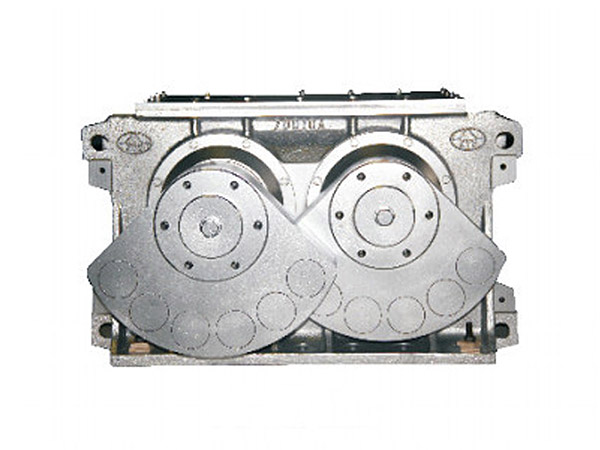

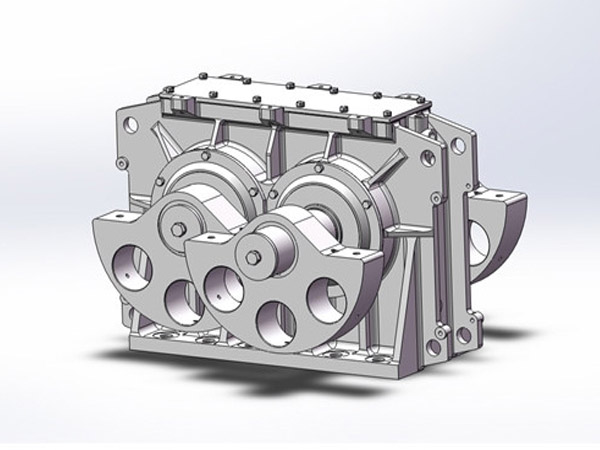

7. Ama-Twin-Shaft Exciters:

Ukusebenza: Ama-twin-shaft exciters asebenzisa ama-shaft amabili avumelaniswe namagiya. Lawa mashafu azungeza ezinhlangothini eziphambene, akhiqize ukunyakaza komugqa kusikrini esidlidlizayo.

Ukusetshenziswa: Ilungele izikrini ezinyakazayo ezinomugqa, ngokuvamile ezitholakala kuzinhlelo zokusebenza ezinzima ezifana nezimayini nokucubungula okuhlanganisiwe.

Uhlobo ngalunye lwe-exciter lufanele izinhlelo zokusebenza ezithile ngokuya ngezinto ezicutshungulwayo, ukusebenza kahle kokuhlola okufunayo, kanye nezidingo zokusebenza.