Benefits of Using a High-Frequency Vibrating Screen Exciter in Industrial Screening

In industries such as mining, quarrying, construction materials, and chemical processing, efficient material screening is a critical step that directly affects product quality, production capacity, and operating costs. As material specifications become more demanding—especially for fine and ultra-fine particles—traditional low-frequency screening methods often struggle to deliver stable and accurate results.

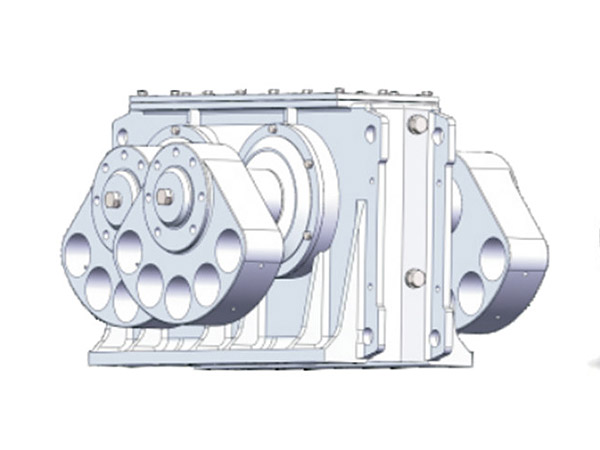

This is where a high-frequency vibrating screen exciter becomes a key performance-enhancing component. By providing controlled, high-speed vibration, it significantly improves screening accuracy, reduces downtime, and increases overall plant efficiency. Below, we explore the major advantages of using a high-frequency vibrating screen exciter in modern industrial applications.

Benefits of Using a High-Frequency Vibrating Screen Exciter

1. Significantly Improved Screening Efficiency

One of the most notable benefits of a high-frequency vibrating screen exciter is its ability to dramatically enhance screening efficiency. The rapid vibration frequency creates intense particle movement across the screen surface, allowing fine materials to pass through the mesh more easily.

Compared with conventional exciters, high-frequency units are especially effective when handling:

Fine sand and mineral concentrates

Slurries and wet materials

Ultra-fine powders used in chemical or industrial processing

By accelerating particle separation, plants can achieve higher throughput without sacrificing accuracy, resulting in more consistent product grading and improved downstream performance.

2. Better Material Stratification and Reduced Blinding

High-frequency vibration promotes effective material stratification. Smaller particles are driven downward toward the screen openings, while larger particles remain on the surface and move toward discharge. This continuous separation process minimizes material layering and reduces common issues such as screen blinding and clogging.

For operations processing ores, aggregates, or high-moisture materials, improved stratification means:

Fewer interruptions during operation

More stable screening performance

Reduced need for manual cleaning or intervention

This contributes to smoother plant operation and higher overall reliability.

3. Compact Structure with High Output Capacity

Another advantage of high-frequency vibrating screen exciters is their ability to deliver strong screening performance with a relatively compact design. Because the exciter increases screening efficiency, the required screen area can often be reduced without compromising output.

This is particularly beneficial for:

Retrofit projects in existing plants

Production lines with limited installation space

Mobile or modular screening systems

A smaller footprint combined with high productivity allows plant designers greater flexibility while maintaining or increasing processing capacity.

4. Lower Wear and Maintenance Requirements

Optimized vibration characteristics help reduce unnecessary impact and friction between materials and the screen surface. As a result, key components such as screen meshes, bearings, and structural parts experience less mechanical stress.

In practical terms, this means:

Longer service life of screen panels

Reduced frequency of maintenance shutdowns

Lower spare parts consumption over time

For plant operators, these benefits translate directly into lower maintenance costs and improved equipment availability.

5. High Adaptability for Different Materials and Processes

High-frequency vibrating screen exciters are highly adjustable and can be fine-tuned according to material properties such as particle size, density, and moisture content. This makes them suitable for a wide range of applications, including:

Coarse and fine aggregates

Metallic and non-metallic ores

Industrial minerals and powders

With proper adjustment, one screening system can handle multiple material types, reducing the need for additional equipment and improving production flexibility.

6. Energy-Efficient Operation

Although high-frequency exciters operate at higher speeds, they are often more energy-efficient than traditional systems. By improving material movement and shortening screening time, less energy is wasted on repeated or ineffective separation.

Over long-term operation, this leads to:

Lower energy consumption per ton processed

Reduced operating costs

Improved sustainability performance

For companies focused on cost control and environmental responsibility, energy efficiency is an increasingly important consideration.

Conclusion

A high-frequency vibrating screen exciter is more than just a component—it is a performance upgrade for the entire screening system. By enhancing separation efficiency, reducing maintenance demands, and supporting flexible material processing, it helps industrial operations achieve higher productivity with lower operational risk.

For mining, construction, and industrial processing plants seeking stable output and long-term cost savings, investing in high-frequency vibrating screen exciter technology is a practical and future-ready solution.