How Exciter Power Affects Screening Efficiency: Insights from a Vibrating Screen Manufacturer

In mining, quarrying, and aggregate processing, screening efficiency directly impacts production output and operating costs. While many operators focus on screen size or mesh selection, exciter power is often underestimated.

From a vibrating screen manufacturer’s perspective, exciter power determines how effectively vibration energy is transferred to the material. When properly matched, it improves separation accuracy, stabilizes throughput, and extends equipment service life. When misapplied, it leads to poor screening results, excessive wear, and unnecessary energy consumption.

What Is Exciter Power in a Vibrating Screen?

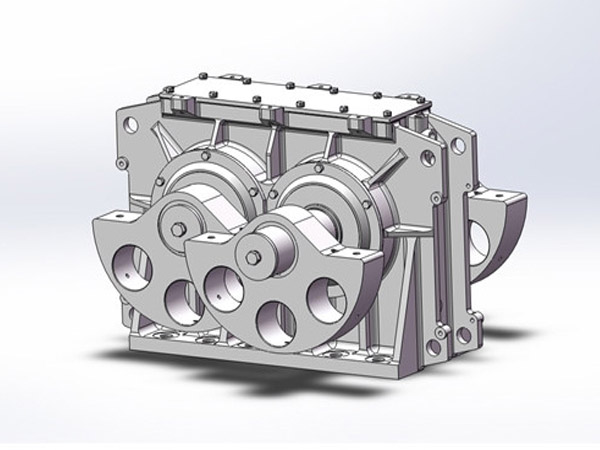

The exciter is the vibration-generating unit of a vibrating screen. Driven by an electric motor, it creates controlled oscillation through eccentric shafts or blocks. Exciter power, typically expressed in kilowatts (kW), defines the amount of energy available to generate vibration force.

In equipment design, exciter power is selected together with:

Vibration frequency

Amplitude

Screen mass and structure

Material load conditions

It is not an isolated parameter, but part of a complete vibration system.

How Exciter Power Influences Screening Efficiency

Material Stratification and Separation Accuracy

Effective screening relies on proper material stratification. Fine particles must move downward to the screen surface, while coarse particles travel toward discharge.

Low exciter power results in insufficient material lift and poor stratification

Fine particles remain trapped, reducing screening efficiency

Optimized exciter power promotes uniform material movement and improves separation accuracy across the entire screen deck

Stable vibration is more important than aggressive vibration.

Throughput Capacity and Material Flow Control

Exciter power directly affects how material moves across the screen.

Moderate power levels ensure continuous flow and adequate screening time

Excessive power may cause material to bounce, reducing effective contact with the screen surface

Higher installed power does not always translate into higher effective throughput.

Screen Deck Wear and Equipment Durability

From a manufacturing standpoint, excessive exciter power creates unnecessary mechanical stress.

Accelerated wear of screen panels and liners

Increased bearing and shaft fatigue

Higher risk of structural damage over long-term operation

Correct exciter power improves screening efficiency while protecting the screen structure.

Energy Consumption and Operating Cost

Increasing exciter power increases energy consumption, but not always performance.

By optimizing exciter power during the design stage, manufacturers can:

Reduce installed motor power

Lower electricity costs

Improve overall equipment efficiency

Energy-efficient vibration design is a key consideration for modern screening systems.

How Manufacturers Optimize Exciter Power Selection

Experienced vibrating screen manufacturers select exciter power based on real operating conditions rather than generic formulas. Key factors include:

Material density, size distribution, and moisture content

Screen dimensions, deck layout, and inclination angle

Required throughput and separation accuracy

Continuous versus intermittent operation

Instead of oversizing, professional design focuses on vibration efficiency and long-term reliability.

Common Exciter Power Selection Mistakes

Oversizing for “Safety Margin”

Oversized exciters often increase wear and energy consumption without improving screening results.

Ignoring Material Variability

Material characteristics change over time. Fixed power settings may not suit all operating conditions.

Treating Exciter Power as an Independent Parameter

Exciter power must be matched with frequency, amplitude, and structural design to be effective.

Conclusion

Exciter power plays a critical role in vibrating screen efficiency, throughput stability, equipment durability, and energy consumption. From a manufacturer’s perspective, the best results come from precise matching—not maximum power.

For operators seeking reliable screening performance, working with a manufacturer that understands exciter power optimization can significantly improve productivity and reduce long-term operating costs.