How to Choose the Right Vibrating Screen Exciter for Mining & Quarry Efficiency

In mining and quarry operations, a vibrating screen exciter is more than just a component—it’s the heartbeat of your screening system. The right exciter ensures precise material separation, maximizes throughput, reduces downtime, and extends equipment lifespan. This comprehensive guide will help you choose the optimal vibrating screen exciter based on your mining requirements, material characteristics, production capacity, and maintenance considerations.

How to Choose the Right Vibrating Screen Exciter for Mining & Quarry Efficiency

1. Understanding the Role of a Vibrating Screen Exciter

A vibrating screen exciter generates the vibration force needed to activate the screen deck. Its performance directly impacts:

Screening accuracy: Consistent vibration ensures even material separation.

Material throughput: Optimized vibration improves productivity.

Equipment stability: Reduces stress on structural components.

Maintenance frequency: Proper selection minimizes wear and service intervals.

Selecting the wrong exciter can lead to reduced output, uneven vibration, structural stress, and premature component failure.

2. Mining Application Requirements: Key Factors

Different mining operations require exciters tailored to the workload and environment. Key considerations include:

a. Screening Capacity & Output Requirements

High-capacity operations → exciters with larger centrifugal force and higher power.

Fine-screening → higher frequency and controlled amplitude for precision.

b. Type of Mining Operation

Open-pit mining: Heavy-duty exciters to withstand continuous operation and impact.

Underground mining: Compact, energy-efficient, reliable exciters for confined spaces.

c. Particle Size Distribution

Large, irregular ore → low frequency, high amplitude.

Fine minerals → high frequency, low amplitude.

Mixed materials → adjustable amplitude or modular exciters.

d. Working Environment

Consider dust, moisture, temperature, and corrosion.

Choose exciters with sealed housing, anti-dust design, and high-grade lubrication.

3. Quarry Material Characteristics & Exciter Matching

Material properties significantly influence exciter selection:

Hardness & Abrasiveness: Granite and basalt → strong force, wear-resistant components. Soft stone → moderate vibration.

Moisture Content: Wet materials → higher amplitude to prevent clogging.

Density & Bulk Weight: High-density → stronger exciters; lightweight → higher frequency.

Material Layer Thickness: Thick layers → low frequency, high amplitude; thin layers → high frequency.

Matching exciters with material characteristics improves screening efficiency and reduces energy consumption.

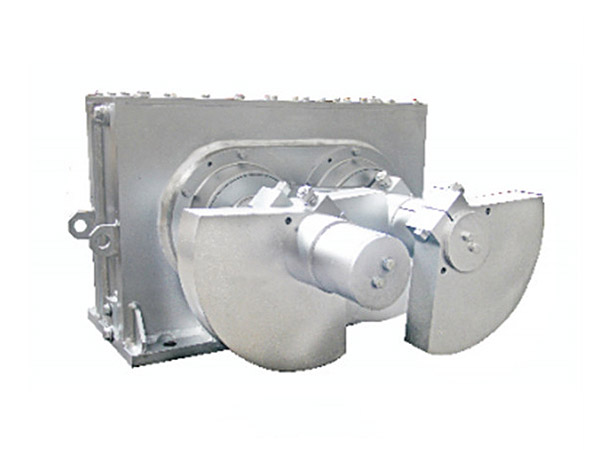

4. Types of Vibrating Screen Exciters & Ideal Scenarios

| Exciter Type | Features | Best Applications |

| Gear Exciters | High load-bearing, stable amplitude | Large ore, primary & secondary screening |

| Vibration Motors | Compact, easy installation | Medium-capacity aggregates, sand & gravel |

| Direct Drive Exciters | High frequency, precision control | Fine ore classification, mineral processing |

| Dual-Shaft Exciters | Strong vibration, excellent balance | Harsh mining environments, large screens |

5. Maintenance Tips for Longevity and Performance

Proper maintenance ensures stable operation and longer lifespan:

Routine Lubrication: Use recommended grease or oil; maintain intervals.

Regular Vibration Testing: Monitor amplitude, frequency, direction.

Bearing Temperature Checks: Detect overheating early.

Gear Wear Inspection: For gear exciters, check teeth for cracks or misalignment.

Bolt Tightness Checks: Vibration can loosen bolts.

Seal & Dust Protection: Maintain dust seals to prevent contamination.

Timely Replacement: Avoid delaying worn component replacement to prevent downtime.

6. Common Mistakes to Avoid

Underpowered exciters for heavy loads

High-frequency exciters for coarse material

Ignoring environmental conditions

Not considering screen deck size, weight, and stiffness

Using low-quality or non-standard components

Mistakes lead to low productivity, high energy consumption, noise, and frequent maintenance.

7. Conclusion: Choosing the Right Exciter for Reliable Mining & Quarry Operations

Selecting the proper vibrating screen exciter is crucial to achieving high screening accuracy, maximizing throughput, and ensuring operational reliability. By evaluating your mining requirements, material characteristics, environmental factors, and maintenance capabilities, you can secure long-term stable performance.

For customized solutions or technical guidance, contact our experts to find the perfect exciter for your mining or quarry project.