How to deal with abnormal operation of vibrating screen exciter?

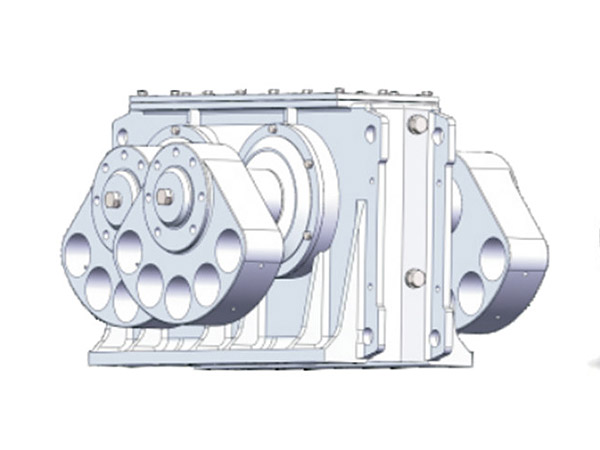

The vibrating screen exciter is an important component that utilizes mechanical vibration. The exciter can make the excited object obtain the vibration amount of the form and size, so as to conduct vibration and strength tests on the object, or calibrate the vibrating screen and sensor.

The vibrating screen exciter can also be used as an excitation component to form a vibrating machine to realize the conveying, screening, compacting, forming and tamping of soil sand and gravel of materials or objects.

1. Damage to the vibration damping system

For example, the failure of the vibration damping spring or the accumulation of materials under the screen will make the vibration damping system uncoordinated, resulting in damage to the vibrating screen exciter.

2. Installation quality problems

Improper adjustment of the exciter gap during the installation process will cause errors in the axial radial joints between the exciter and the motor, and the universal coupling, as well as the relative position of the exciter eccentric block. Excessive vibration of the vibrator produces high temperature, which seriously affects the normal operation of the vibrating screen.

3. Improper use

Due to the sudden shutdown of production or other equipment failures, the screen box is filled with mineral materials, and if the exciter is restarted under heavy load, it is very easy to cause damage to the universal joint of the exciter and other parts.

4. Lubrication failure

The vibration exciter is manually lubricated, and oil is applied every 8 hours. The lubricant is molybdenum disulfide grease. The vibrating screen is in a high temperature and dusty environment. The manual lubrication pump is far away from the lubrication point, especially in winter. , The room temperature is lower, which is more likely to cause the grease to solidify and agglomerate, and the oil cut will cause the bearing to wear and fail.

The exciter is the key component in the vibrating screen. In the process of use, once the above abnormal situation occurs in the exciter, it is very important to find out improvement measures through the analysis of the cause of the failure, and to improve the service life of the exciter.