Vibrating Screen Exciter Selection Guide for Mining and Quarry Operations

In the mining, quarrying, and aggregate processing industries, vibrating screens are core equipment for ensuring material grading accuracy and production efficiency, while the vibrating screen exciter is the key component for achieving efficient vibrating screening. Selecting the right exciter can significantly improve screening efficiency and reduce equipment downtime and maintenance costs. Inappropriate selection may lead to insufficient vibration, material blockage, or increased energy consumption, thus affecting the overall production process.

This guide provides practical methods for selecting vibrating screen exciters for mining and quarrying operations, including making reasonable selections based on material characteristics, production requirements, equipment specifications, and working environment, helping companies achieve efficient, safe, and economical screening operations.

1.Understanding the Role of a Vibrating Screen Exciter

A vibrating screen exciter generates the necessary vibration force to activate the screening deck. It determines the screen’s amplitude, frequency, and overall vibration pattern, directly affecting:

Screening accuracy

Material throughput

Equipment stability

Wear and maintenance frequency

Selecting the wrong exciter can lead to reduced capacity, uneven vibration, structural stress, or premature component failure.

2.Mining Application Requirements: Key Factors to Consider

Different mining conditions require different vibration forces and structural designs. When choosing an exciter, evaluate the following:

(1) Screening Capacity & Output Requirements

High-capacity mining operations require exciters with larger centrifugal force and higher power.

For fine-screening or classification processes, exciters with higher frequency and controlled amplitude are preferred.

(2) Type of Mining Operation

Open-pit mining: Requires heavy-duty exciters that withstand continuous operation and strong impact loads.

Underground mining: Focuses on compact structure, energy efficiency, and reliability in confined environments.

(3) Particle Size Distribution

Large, irregular ore → low frequency, high amplitude

Fine minerals → high frequency, low amplitude

Mixed materials → adjustable amplitude or modular exciters

(4) Working Environment

Consider dust levels, moisture, temperature, and corrosion. Choose exciters with sealed housing, anti-dust design, and high-grade bearing lubrication systems.

3.Quarry Material Characteristics and Their Impact on Exciter Selection

Quarry materials vary widely depending on the geological layer and processing requirements. The exciter should match material characteristics such as:

(1) Hardness & Abrasiveness

Granite, basalt, and hard limestone require strong excitation force and wear-resistant components.

Softer stones like sandstone require moderate vibration intensity.

(2) Moisture Content

Wet materials tend to adhere and block screens.

→ Using higher amplitude can help prevent clogging.

(3) Density & Bulk Weight

High-density stones need more powerful exciters for smooth stratification.

Lightweight aggregates require higher frequency for precise separation.

(4) Material Layer Thickness

Thick material layers: low-frequency, high-amplitude excitation

Thin material layers: high-frequency excitation for accuracy

Matching material characteristics with the correct exciter improves both screening efficiency and energy consumption.

4.Types of Vibrating Screen Exciters and Their Suitable Scenarios

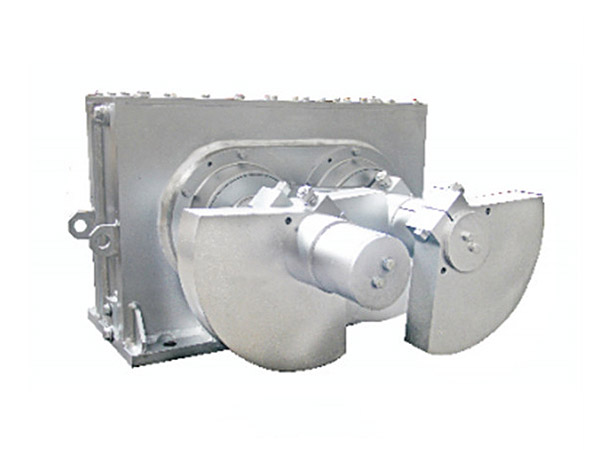

(1) Gear Exciters

High load-bearing capacity

Suitable for heavy-duty mining screens

Stable amplitude output

Best for: large ore, primary and secondary screening

(2) Vibration Motors

Compact design and easy installation

Suitable for standard quarry applications

Best for: medium-capacity aggregates, sand & gravel processing

(3) Direct Drive Exciters

High frequency, precision control

Low noise, ideal for fine screening

Best for: fine ore classification, mineral processing plants

(4) Dual-Shaft Exciters

Strong vibration force

Excellent dynamic balance

Best for: harsh mining environments and large screen decks

5.Maintenance Tips to Improve Exciter Performance and Lifespan

Proper maintenance enhances equipment reliability and reduces downtime. Useful practices include:

✔ Routine Lubrication

Use high-quality grease or oil recommended by the manufacturer.

Maintain the correct lubrication interval to prevent bearing overheating.

✔ Regular Vibration Testing

Check amplitude, frequency, and vibration direction to ensure stable performance.

✔ Monitor Bearing Temperature

Abnormal heat may indicate lubrication failure or bearing wear.

✔ Check Gear Wear (for gear exciters)

Inspect gear teeth regularly for wear, cracks, or misalignment.

✔ Bolt Tightness Inspection

Vibration can loosen bolts over time—especially screen body and exciter mounting points.

✔ Seal and Dust Protection

Ensure dust seals remain intact to prevent contamination inside the exciter housing.

✔ Replace Worn Components Promptly

Delaying replacement increases the risk of severe damage and downtime.

6.Common Mistakes to Avoid When Selecting a Vibrating Screen Exciter

Choosing an underpowered exciter that cannot handle heavy loads

Using high-frequency exciters in coarse material screening

Ignoring environmental factors such as dust, humidity, and temperature

Not accounting for screen deck size, weight, and structural stiffness

Selecting non-standard or low-quality components to reduce cost

These mistakes can lead to low productivity, excessive noise, high energy consumption, and unscheduled maintenance.

7.Conclusion: Selecting the Right Exciter Ensures Reliable Mining & Quarry Productivity

In mining and quarrying operations, a well-matched vibrating screen exciter can improve screening accuracy, increase throughput, and extend equipment life. By carefully evaluating mining requirements, material characteristics, environmental conditions, and maintenance capabilities, operators can achieve stable and efficient screening performance.

For professional support in selecting vibrating screen exciters for mining and quarrying applications, collaborating with experienced equipment suppliers or technical teams can significantly reduce operational risks and improve long-term production efficiency.

If your mining or quarry project requires high-quality exciters or customized screening solutions, feel free to contact our technical team for professional selection support.

-80x80.jpg)